Class 10.9 high strength insulated joint bolts

Send Inquiry

Class 10.9 high strength insulated joint bolts are used in heavy machinery and they can withstand extreme loads. For example, mining equipment or hydraulic presses, and insulating sleeves (such as nylon or PVC) can block the current.

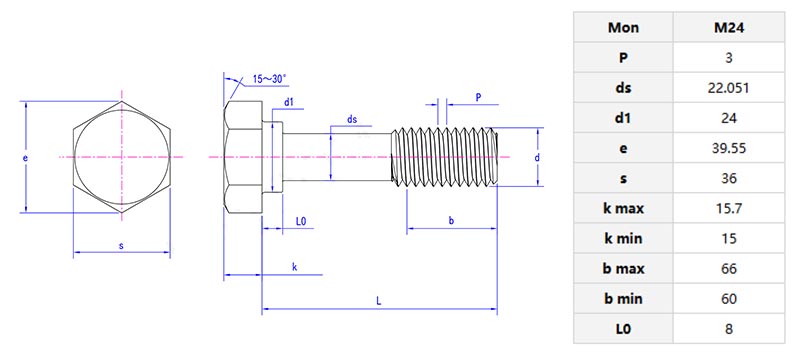

Product details and parameters

Class 10.9 insulated joint bolts are usually made of medium carbon steel or low boron alloy steel. After quenching and tempering treatment, they reach the high strength standard of grade 10.9. They can firmly fix the tracks and turnouts, ensuring the stable operation of freight trains.

The minimum tensile strength of the high strength insulated joint bolts can reach 1040 megapascals, and the minimum yield strength is 940 megapascals. They can stably withstand large tensile and compressive forces, and the connection is extremely firm. It can effectively block the conduction of current or prevent interference from other media.

For the manufacturing of power equipment, Class 10.9 high strength insulated joint bolts are installed in places such as transformers and distribution cabinets. When a transformer is in operation, it generates a strong electric field. The internal component connections must have sufficient strength but also prevent the electricity from running freely to avoid faults such as short circuits. High strength insulated joint bolts can just meet these strict requirements and ensure the safe and stable operation of power equipment.

Product features

The insulating part of Class 10.9 high strength insulated joint bolts uses special insulating materials, such as some polymer insulating materials. These materials have good insulation properties and can effectively prevent electric current from passing through. Moreover, under normal usage conditions, the insulation performance can be maintained for a long time. Even in a slightly humid or slightly corrosive gas environment, it can still stably play an insulating role.