Carbon Steel Floating Long Clinching Nut

Send Inquiry

Since this carbon steel floating long clinching nut is rust-resistant, it doesn’t need much maintenance.But it's also worth checking from time to time to see if there's any debris stuck in the threads or any obvious physical damage.

If it needs cleaning, use mild soapy water or solvents that work with stainless steel. Don’t use rough cleaners or steel brushes on it,those can mess up the surface and maybe cause contamination. Keep it simple, and the nut should stay in good shape without a lot of effort.

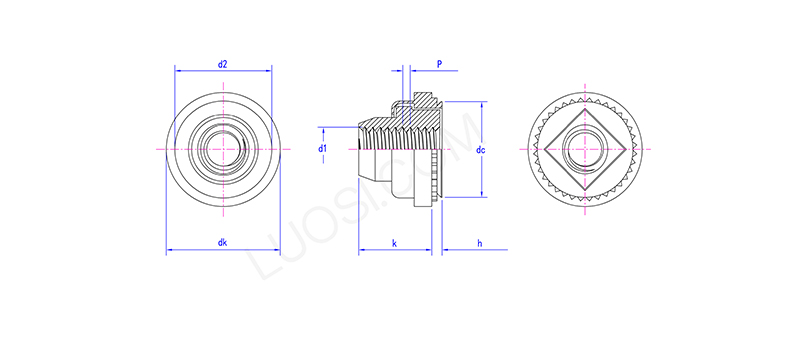

| Mon | M3-1 | M3-2 | M4-1 | M4-2 | M5-1 | M5-2 | M6-2 |

| P | 0.5 | 0.5 | 0.7 | 0.7 | 0.8 | 0.8 | 1 |

| d1 | M3 | M3 | M4 | M4 | M5 | M5 | M6 |

| dc max | 7.35 | 7.35 | 9.33 | 9.33 | 10.29 | 10.29 | 13.06 |

| dk max | 9.52 | 9.52 | 11.56 | 11.56 | 12.32 | 12.32 | 15.62 |

| dk min | 8.76 | 8.76 | 10.8 | 10.8 | 11.56 | 11.56 | 14.86 |

| h max | 0.97 | 1.38 | 0.97 | 1.38 | 0.97 | 1.38 | 1.38 |

| k max | 4.83 | 4.83 | 5.34 | 5.34 | 6.86 | 6.86 | 7.88 |

| d2 max | 7.37 | 7.37 | 9.28 | 9.28 | 10.29 | 10.29 | 12.96 |

Features:

This carbon steel floating long clinching nut is a great value because it's easy to install (thanks to the floating design), strong in thin materials (with the long clinch), and reliable over time (because of the stainless steel). It makes assembly faster, cuts down on the need for welding or complicated brackets, and lowers the chance of rust-related problems later on.

Choosing this nut means you're getting a durable, efficient fastener that doesn't need much maintenance. The floating part takes care of alignment issues during installation, the long clinch gives it strength in thin metal, and the stainless steel keeps it from rusting. It's a smart choice if you want a fastening solution that just works without extra hassle.

Advantages:

Q: What are the main advantages of floating long rivet nuts compared to weld nuts or rivet nuts?

A: This carbon steel floating long clinching nut has some big pluses. It cuts out the heat warping and costs that come with welding. Installing it is faster than using rivet nuts, and it gives a flush finish on both sides of the metal. Plus, it makes a strong, permanent joint that’s sealed tight.

300 Series stainless steel is rust-resistant and suitable for automated assembly lines, especially for threaded connections requiring speed, a secure connection, and durability and corrosion resistance. It is easy to install, requires no welding, and fastens fast, saving time and costs while providing long-term, stable connections.