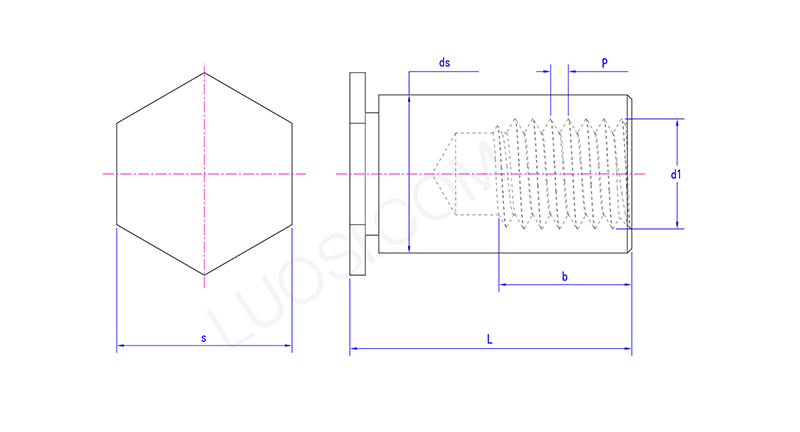

Carbon Steel Blind Hole Hexagon Riveted Nut

Send Inquiry

Alright, that carbon steel blind hole hexagon riveted nut gets the job done in rough conditions. Using stainless steel with the riveted design means it doesn't shake loose from vibrations like some fasteners, and it generally doesn't get fussy with heat or cold changes. The blind hole part is important,it protects the threads while you're setting it, so they stay usable even if you're swapping bolts in and out a bunch of times.

These hold their grip pretty well, take a good amount of tightening force, and don't usually wear out fast from repeated use. Plus, the flat head sits flush, so it won't catch on stuff, and honestly, it just looks tidier.

How to clean and maintain?

Looking after that carbon steel blind hole hexagon riveted nut? Mostly, just keep the threads clean. Don't let gunk or rust build up in there,especially if it's in a rough spot. It's smart to check them once in a while for damaged threads, rust (though if it's stainless steel, that helps), or if they seem loose.

Usually, a scrub with warm soapy water and a soft brush does the trick. Skip the cleaners with chlorine. Since these blind hole flat head hexagon riveted nuts-carbon steel are stainless steel and riveted in place, they mostly just last ages with hardly any fuss. That keeps costs down over time.

| Mon | 440 | 6440 | 632 | 8632 | 832 | 032 |

| P | 40 | 40 | 32 | 32 | 32 | 32 |

| d1 | #4 | #4 | #6 | #6 | #8 | #10 |

| ds max | 0.165 | 0.212 | 0.212 | 0.28 | 0.28 | 0.28 |

| ds min | 0.16 | 0.207 | 0.207 | 0.275 | 0.275 | 0.275 |

| s | 0.187 | 0.25 | 0.25 | 0.312 | 0.312 | 0.312 |

International Quality Standards:

Our carbon steel blind hole hexagon riveted nut meet major international standards like ISO 15977, DIN 7337, or the Chinese GB equivalents. They’re made to strict size, material, and strength specs,they’ll hold up against pulling or twisting forces. If you need certification papers for your project or to meet local rules, just let us know and we can provide them.