Blackening Treatment Double Ferrule Nut

Send Inquiry

The Blackening Treatment Double Ferrule Nut is basically a type of nut used to connect and seal small pipes, especially where you really don't want leaks. You'll often find it in hydraulic and pneumatic setups—like on the oil lines of factory machines, the air hoses for pneumatic tools, or the hydraulic lines in diggers. Its design with two ferrules helps it grip the pipe tightly to stop any fluid or gas from escaping, even when the pressure is high. The black coating on it cuts down on glare and gives it a bit of rust protection, which is why you'll see it used in indoor machine rooms or semi-outdoor spots where you don't want a lot of light bouncing around.

This kind of nut is pretty common in cars and boats too. In vehicles, it's used on things like fuel lines, brake lines, and coolant hoses to keep fluids flowing properly while you're driving. On boats, you might find it on smaller pipes in the engine room, as the black finish can handle a damp environment okay. It also gets used in some industrial pipe systems for things like water or certain chemicals, mainly because it seals well and is fairly easy to put together. You don't really need special tools to install it, so it works for both professional jobs and basic maintenance work.

Product Packaging

Alright, so when it comes to packing these Blackening Treatment Double Ferrule Nuts, the main idea is to make sure they don't get banged up on the way to you or while sitting in storage. There's no fancy packaging or anything—it's purely functional.

If you're ordering just a few, like for a sample or a small project, each nut gets its own little clear plastic bag first. This is to keep that black finish from getting scratched and to stop them from rubbing against each other. A bunch of these bags then go into a good, thick cardboard box. We usually put some foam or padding around the bags inside the box too, so if the box gets moved around or stacked with others, the nuts inside don't get jostled and damaged.

For bigger bulk orders, things are a bit more organized. The nuts are separated by size and packed neatly into strong cartons. These boxes have a waterproof plastic liner on the inside, which is really useful. It helps keep moisture out, which is important if they're going on a long boat trip or if they'll be stored somewhere a bit damp. For really large shipments, we put these filled cartons on standard wooden pallets and secure everything tightly with plastic straps so nothing shifts around during transport.

Q&A Session

Q: Can Blackening Treatment Double Ferrule Nut be used in outdoor humid environments?

A: So, the black coating on these Double Ferrule Nuts gives them a bit of rust protection, but it's really meant for places that are mostly dry—think indoors or maybe under some cover outdoors.

If you're planning to use them outside where it's often damp, or especially near the sea where there's salt in the air, this black finish probably won't hold up well for the long term. In those cases, you'd be better off looking for nuts made from stainless steel instead.

While the blackening can handle a little moisture here and there, if it's constantly wet or in high humidity, you might start to see rust spots form over time. So if you do end up using them in a spot that's not perfectly dry, it's a good idea to check on them once in a while to make sure they're still holding up okay.

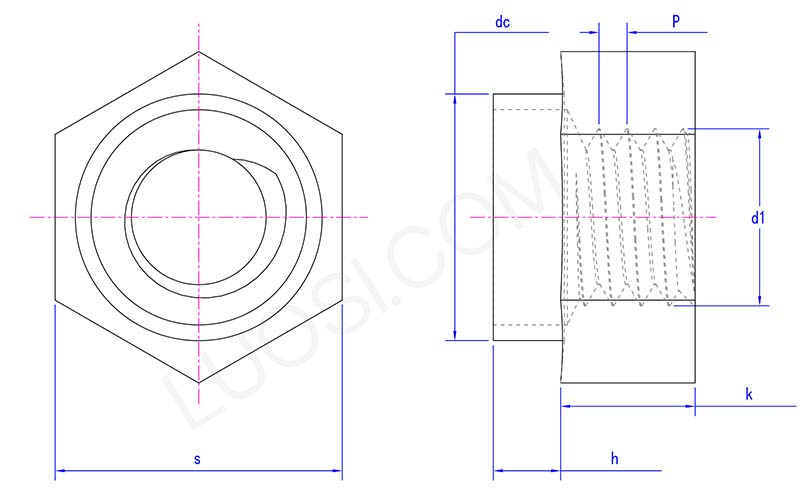

|

Mon |

M3-2 |

M4-1.5 |

M4-2 |

M4-3 |

M5-2 |

M5-3 |

M5-4 |

M6-3 |

M6-4 |

M6-5 |

M6-6 |

|

P |

0.5 | 0.7 | 0.7 | 0.7 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 |

|

d1 |

M3 |

M4 |

M4 | M4 | M5 | M5 | M5 | M6 | M6 | M6 | M6 |

|

dc max |

4.98 | 5.98 | 5.98 | 5.98 | 7.95 | 7.95 | 7.95 | 8.98 | 8.98 | 8.98 | 8.98 |

|

h max |

2.1 | 1.6 | 2.1 | 3.1 | 2.1 | 3.1 | 4.1 | 3.1 | 4.1 | 5.1 | 6.1 |

|

h min |

1.9 | 1.4 | 1.9 | 2.9 | 1.9 | 2.9 | 3.9 | 2.9 | 3.9 | 4.9 | 5.9 |

|

k max |

3.25 | 4.25 | 4.25 | 4.25 | 5.25 | 5.25 | 5.25 | 6.25 |

6.25 |

6.25 |

6.25 |

|

k min |

2.75 | 3.75 | 3.75 | 3.75 | 4.75 | 4.75 | 4.75 | 5.75 | 5.75 | 5.75 | 5.75 |

|

s max |

6.25 | 7.25 | 7.257 | 7.25 | 9.25 | 9.25 | 9.25 | 10.25 | 10.25 | 10.25 | 10.25 |

|

s min |

5.75 | 6.75 | 6.75 | 6.75 | 8.75 | 8.75 | 8.75 | 9.75 | 9.75 | 9.75 | 9.75 |