Aluminum Alloy Double Ferrule Nut

Send Inquiry

This aluminum alloy double ferrule nut made of aluminum alloy is mainly used in the aerospace, automotive and electronics industries. These fields require two key characteristics: good strength-to-weight ratio and rust resistance.

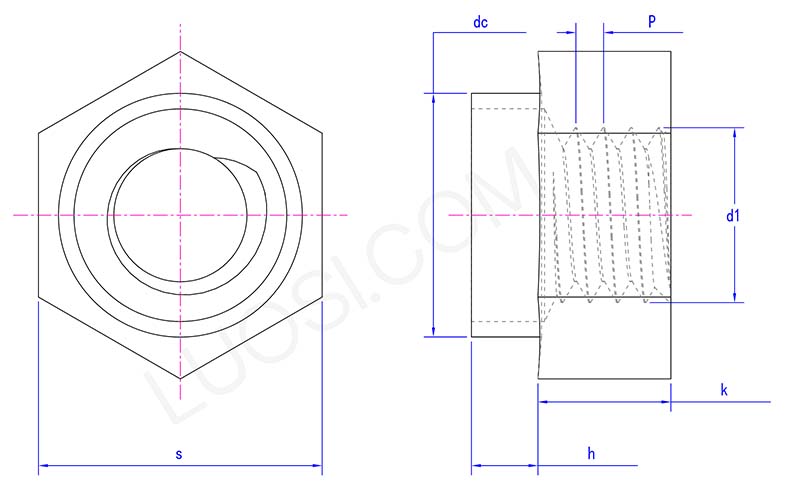

Its design is a bit special - it has a hexagonal body, so it can be operated with regular tools, and it also has a handle similar to a rivet. During installation, this handle will expand. This will form a permanent thread that will not loosen due to vibration, even on thin plates or soft materials.

On one side, this aluminum nut is flat, so it is very suitable for aerodynamic surfaces and compact components. The aluminum itself is naturally silver in color, but you can perform an anodizing process on it to obtain different colors - such as black, red or blue. This helps with identification or meeting the appearance you desire.

Moreover, its cost-effectiveness is also very high: aluminum is not expensive, and it can be installed with just one operation on one side, thus saving time.

Our Advantages

We conduct strict quality inspections on each aluminum alloy double ferrule nut,from the selection of raw materials to the final packaging. These aluminum alloys meet the corresponding standards. During the manufacturing process, we strictly check their dimensions and test the effect of the rod expansion.

Before shipment, we will conduct final inspections to ensure that each batch of products meets the specified performance standards. If you need, we also have certifications such as ISO 9001.

For shipping, we deliver these nuts to all over the world in a fast manner - either by air or by sea. Due to their light weight, the shipping costs are also lower. We pack them in sturdy cardboard boxes and wrap them with waterproof materials so they won't get damaged, rusted or damp during transportation.

We offer volume discounts for orders over 50,000 at a time. This high-quality, lightweight fastener is an economical choice.

Mon

M4-2

M4-3

M5-2

M5-3

M5-4

M6-3

M6-4

M6-5

M6-6

M8-3

M8-4

P

0.7

0.7

0.8

0.8

0.8

1

1

1

1

1.25

1.25

d1

M4

M4

M5

M5

M5

M6

M6

M6

M6

M8

M8

dc max

5.98

5.98

7.95

7.95

7.95

8.98

8.98

8.98

8.98

10.98

10.98

h max

2.1

3.1

2.1

3.1

4.1

3.1

4.1

5.1

6.1

3.1

4.1

h min

1.9

2.9

1.9

2.9

3.9

2.9

3.9

4.9

5.9

2.9

3.9

k max

4.25

4.25

5.25

5.25

5.25

6.25

6.25

6.25

6.25

6.25

6.25

k min

3.75

3.75

4.75

4.75

4.75

5.75

5.75

5.75

5.75

5.75

5.75

s max

7.25

7.25

9.25

9.25

9.25

10.25

10.25

10.25

10.25

12.95

12.95

s min

6.75

6.75

8.75

8.75

8.75

9.75

9.75

9.75

9.75

12.45

12.45

Load capacity and temperature range

How much weight can an aluminum alloy double ferrule nut actually support? This depends on several factors: the thickness of the material, the size of the drilled hole, and the specific size/grade of nut you choose.

Those common stainless grades (304 and 316) are strong and work fine across a big temp range,think roughly -200°C to +400°C (-328°F to +750°F) for brief stints.

We provide actual data, such as shear strength or torque, and we can provide specification sheets that list the exact load capacity of each aluminum alloy ferrule nut stainless steel model.