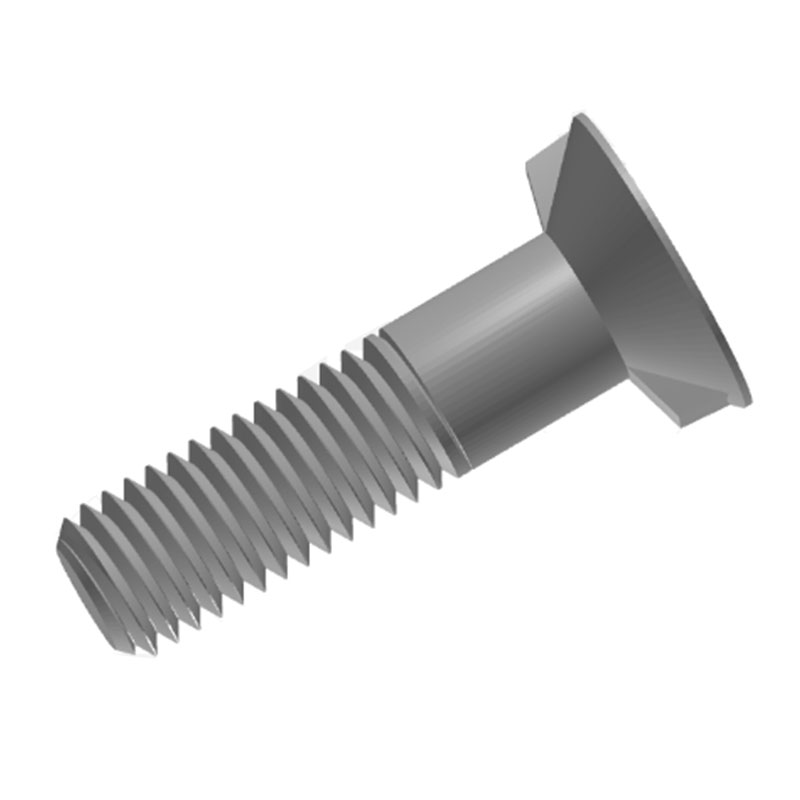

80°Countersunk head bolts

Send Inquiry

The head of the 80°Countersunk head bolts is uniquely tilted at 80° and can be flush with the surface of the material to which they are fastened after installation. The screw part is equipped with standard threads, which is convenient for matching with the nut to achieve fastening.

Product details

They are used for assembling high-end bicycle parts, such as installing carbon fiber gearboxes or brake seats. Using them can prevent debris or clothes from getting stuck. The bolt can be neatly inserted into the Countersunk holes of the preformed frame, evenly distributing the clamping force on the fragile carbon fiber. Prevent material damage during high-pressure gear shifting or sudden braking.

80°Countersunk head bolts can attach steel table legs to a wooden tabletop, and they have a direct surface. They can be embedded flush into the wood without causing the thin edges to crack. The bolts are tightly wedged into the pre-punched holes of the steel frame to prevent rotation during assembly. Form a wobbly joint while completely concealing the fasteners.

They are used for aircraft skin panels. The precise 80° Angle perfectly matches the standard aviation countersunk hole. When installed flush, they can keep the airflow above the wings and the fuselage smooth. This eliminates the jolts that generate resistance.

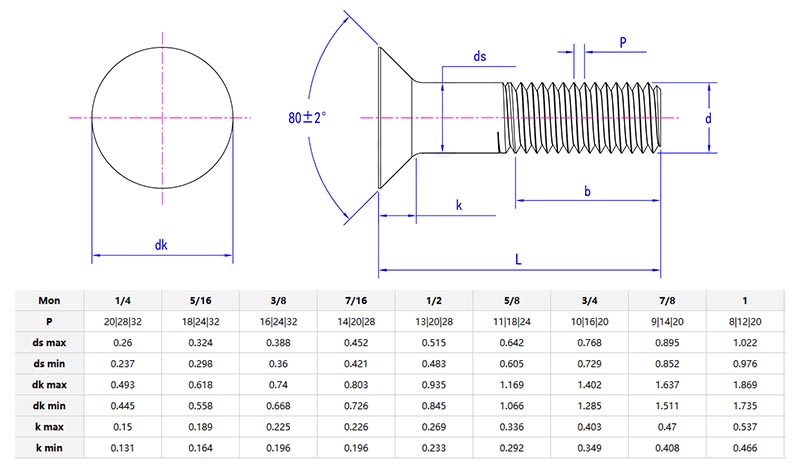

Product parameters

Product selling point

The surface of 80°Countersunk head bolts is smooth and beautiful, and the connection is firm and secure. Using it to install can keep the fixed surface flat, which is stable and beautiful without affecting the placement of other objects. It can withstand considerable tension and shear force, and the connection part is still stable and not easy to loosen after long-term use.