Torque Rich Torsion Spring

Send Inquiry

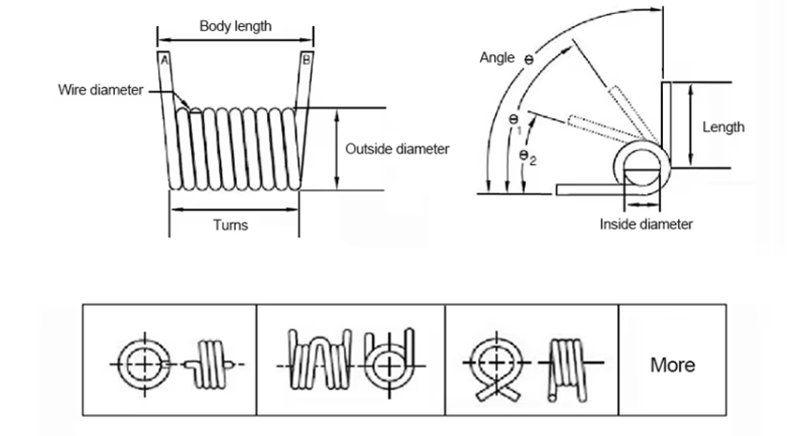

The Torque Rich Torsion Springs have a very distinctive appearance. They have a spiral-shaped body that is tightly wound and has two legs or arms extending from each end.

These legs are the key to their functionality - they act like levers to apply torsional force. The main spiral part is usually tightly wound together to keep its diameter small, yet still capable of generating a large amount of torsional force.

The angle, length, and direction of the legs are all designed according to specific purposes. This is why they are easily recognizable, and their purpose can usually be determined by their design.

Product Details

Torque Rich Torsion Springs are very practical because they perform extremely well as a mechanical means of storing and releasing torsional energy.

If you require custom designs, then engineering costs will be involved. However, for standard-sized springs, they can be mass-produced, resulting in lower costs.

They can also be used for a long time and require little maintenance. This increases their value - manufacturers in the automotive industry, industrial work, and consumer goods sectors can ultimately save costs because these springs are not prone to damage and can work consistently and stably.

FAQ

Q:Can you produce custom Torque Rich Torsion Springs with specific leg configurations or unusual end forms?

A:Absolutely. We specialize in custom Torque Rich Torsion Spring designs. The legs or ends can be manufactured in various forms—short or long hooks, straight or offset tangs, or even complex machined ends. Providing us with a detailed drawing or sample of the required leg configuration for your Torque-Rich Torsion spring allows us to produce a part that integrates perfectly into your assembly, ensuring optimal force application and fit.