Straight Pin

Send Inquiry

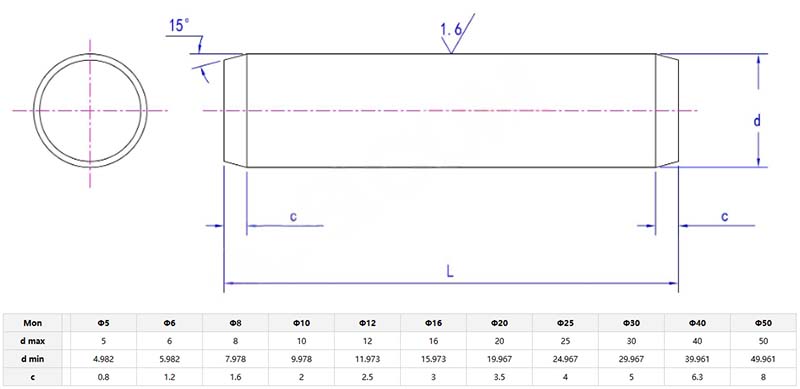

Straight pin come in diameters from 1 mm to 50 mm and lengths up to 300 mm. They’re used in everything from small mechanical systems to big industrial machines. Tolerances like ISO h6 or h7 make sure they fit exactly in holes that have been reamed (drilled to a precise size). Both metric and imperial standards are available to meet manufacturing needs around the world. If you need a custom size, they can add chamfered or rounded edges to prevent damage when you install them. Companies usually provide detailed technical drawings and CAD models to make it easier to include these pins in existing designs.

Surface coating

If you want straight pin to last longer, you can give them surface treatments like zinc plating, black oxide, or electropolishing. Zinc plating basically stops rust,good for outdoor stuff. Black oxide makes them tougher against daily wear and helps parts slide smoother. For hospitals or kitchens where cleanliness matters, electropolished stainless steel pins work best because they don’t trap dirt. In really heavy-duty situations like car engines, they even use special coatings like DLC (kinda like super-tough carbon layers) to survive constant rubbing and heat. These treatments just help the pins hold up better when they’re getting beat up daily.

Guaranteed corrosion resistance

Q: How do I ensure the corrosion resistance of straight pin in harsh environments?

A: You can choose stainless steel cylindrical pins or ask for surface treatments like passivation, electroplating, or thermal diffusion coating. These processes help the pins resist rust and chemicals better. If you’re using them in marine areas or places with a lot of moisture, 316 stainless steel or zinc-nickel coatings are good options. Make sure to check their salt spray test results (like 500+ hours) to see how long they’ll last in corrosive conditions.