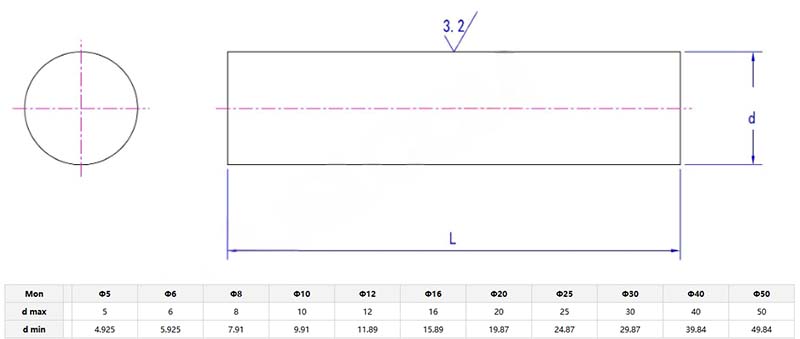

Stainless Steel Cylindrical Pin

Send Inquiry

Stainless steel cylindrical pins can be found in industries that require precise alignment of parts, such as automotive transmissions, robotics, and construction machinery.They hold gears in place, align hydraulic parts, and position sensors in electronics. In medical equipment, stainless steel ones make sure the joints stay clean and don’t react with anything. They’re even used in wind turbines and other renewable energy setups,they can handle tough, high-stress conditions. Whether used in small electronics or large machinery, these pins are used in a variety of industries and are rugged and durable.

Materials

Stainless steel cylindrical pins are made of materials such as alloy steel, stainless steel or titanium. They are durable and strong and will not deform or break due to external forces.If you heat-treat alloy steel pins, they get super hard (like 60 HRC level) and can handle repeated stress, so they’re good for heavy machinery. Stainless steel ones work better in wet or corrosive spots, while titanium pins are lighter but still strong enough for planes and rockets. Choosing the right material just means the pins won’t fail under high heat, heavy loads, or chemical exposure, depending on what your industry requires.

Carrying capacity

Q: What load-bearing capacities do stainless steel cylindrical pin offer, and how are they tested?

A: The load a cylindrical pin can handle depends on how strong the material is and how thick the pin is. Carbon steel pins that are hardened to 45-50 HRC can usually take shear loads up to 1,500 MPa. They test things like tensile strength, how well they resist shear, and fatigue using standards like ISO 898-1. Tell your supplier about the stress your application will have whether it’s static or dynamic loads,to make sure you pick pins rated for your safety needs.