Space Optimizing Compression Spring

Send Inquiry

Space Optimizing Compression Springs are commonly used in medical equipment, such as syringes and implants. These products must be sterile and must function reliably.

They are usually of a small diameter and the force curve remains consistent. Our pricing is highly competitive and offers benefits to bulk purchasers: if your order volume is 800 pieces or more, you can enjoy discounts to reduce your overall purchase costs.

You can choose springs with biocompatible coatings and colors. We use priority mail for quick delivery. This method works well for urgent delivery needs. The shipping cost is also reasonable.

We use anti-disassembly and cushioned packaging to ensure that the springs will not be damaged during transportation. To conduct quality checks, we will perform waterproof tests and pre-delivery inspections. This ensures that each spring meets the FDA and ISO 13485 standards - these are the regulatory requirements for medical use.

Product Details

Space Optimizing Compression Spring is commonly used in household appliances, such as washing machines and refrigerators. They help reduce vibrations and enable the functioning of closing devices like refrigerator doors or washing machine components.

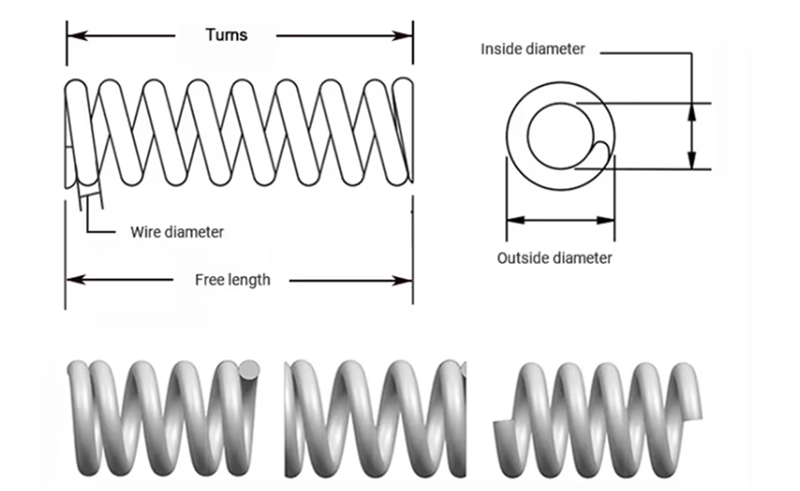

The coils of these springs are arranged very regularly, and the metal material used is not only durable in itself, but also directly extends the overall service life of the spring. Therefore, they have a long service life. Our automated production model effectively reduces intermediate costs, allowing us to offer you more competitive pricing. For orders of 1,200 pieces or more, you can enjoy an additional 7% bulk purchase discount, further reducing your procurement costs.

The standard surface treatment is nickel plating, which is a common appearance. To make receiving your goods worry-free, we have teamed up with many reliable transportation companies around the world to provide fast delivery and affordable prices. The packages are reinforced to reduce damage during bumpy transportation and ensure that the items are intact.

Each spring undergoes waterproof and strength tests. We also have a CE mark to prove our quality control measures - so you know they meet the correct standards.

FAQ

Q:What is the difference between squared/ground ends and plain ends on a Space Optimizing Compression Spring?

A:Squaring and grinding the ends of a spring creates a flat, perpendicular bearing surface. This provides superior stability and ensures the force is applied axially, preventing buckling under high loads. A plain end spring is less expensive but can be unstable. For applications requiring precise, straight-line compression, we strongly recommend squared and ground ends for optimal performance.