Smooth Unwinding Spiral Spring

Send Inquiry

The packaging of the Smooth Unwinding Spiral Spring components is designed very securely, which ensures that their precise spiral structure will not be bent or damaged.

Each spring is placed separately in the corresponding area of the plastic or cardboard container - this ensures that they will not move at all. Then, these containers are tightly packed into a sturdy cardboard box.

For high-value or precision-engineered items, such as springs used in watches, a dedicated packaging solution is required that is different from that of ordinary items. It is designed to withstand impacts, vibrations and static electricity. This ensures that each spiral spring reaches its destination in perfect condition.

Strong packaging

If the Smooth Unwinding Spiral Springs are properly packaged, the possibility of their damage during transportation will be extremely low.

We use a special partitioned packaging method, aiming to protect the springs from physical impacts, pressure, and any movements that could cause deformation or bending of the spiral. You can rest assured that the spiral spring components you order will arrive without any issues - their shape and working method will not be affected.

FAQ

Q: What information do you need from me to provide a prototype and quote for a spiral spring?

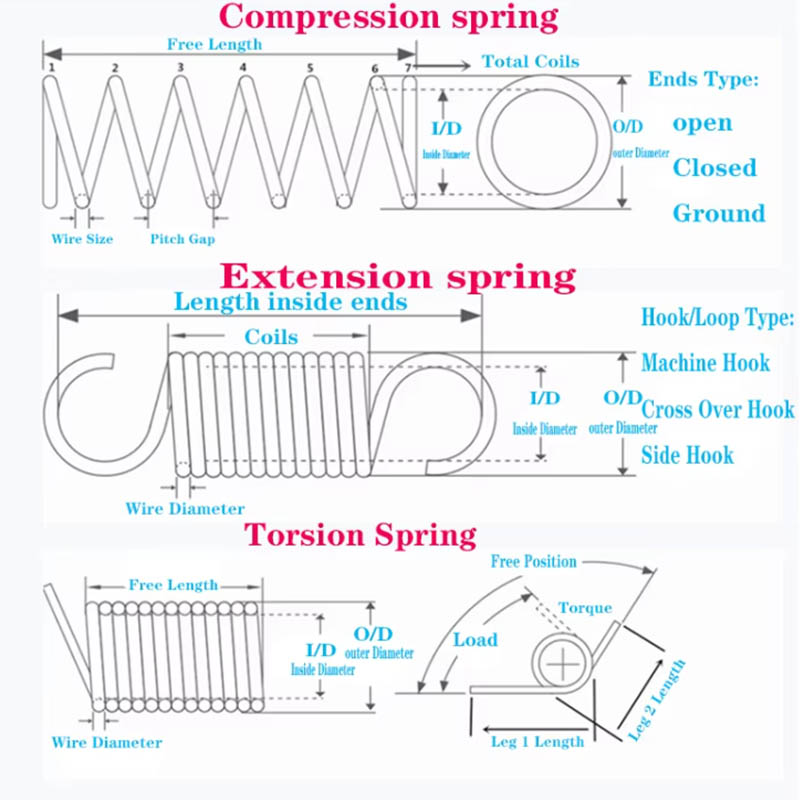

A: To ensure we can provide you with an accurate quote and prototype for your "Smooth Unfolding Coil Spring," we must first obtain the following five key parameters: the specific dimensions of the housing, including the inner and outer diameters; the core parameters of the strip material, including thickness and width; the required torque value (in inch-pounds or Newton-millimeters); the required number of spring rotations; the spring material selection; and the subsequent use environment description. A diagram of the assembly is extremely helpful for our engineers to design the optimal Smooth Unwinding Spiral Spring for your product.