Screw Eye

Send Inquiry

The materials used in screw eye really matter for how they work. Stainless steel types, like 304 or 316, hold up well in rust-prone places, especially marine setups. Carbon steel ones are tough and can handle heavy lifting in industrial jobs.Go through heat treatment to make them stronger, so they don’t bend or break under heavy loads. Aluminum versions are lighter but still sturdy, which is useful for jobs where weight matters.

Picking the right material affects how much weight they can safely hold and where you can use them. This ensures eye bolts are up to the task in different industries, keeping things safe and making them last longer.

Product details:

It’s important to check screw eye regularly to keep them safe. Look for cracks, messed-up threads, or rust—if you see any problems, swap them out. Lubricate the threads now and then to stop them from getting stuck, especially with stainless steel ones. Keep them away from chemicals that can eat away at the coating. Store them in dry places to keep rust away. After using them for heavy jobs, retest their weight limits if needed. Taking care of them helps them last longer and keeps things safe, which is really important for risky lifting tasks.

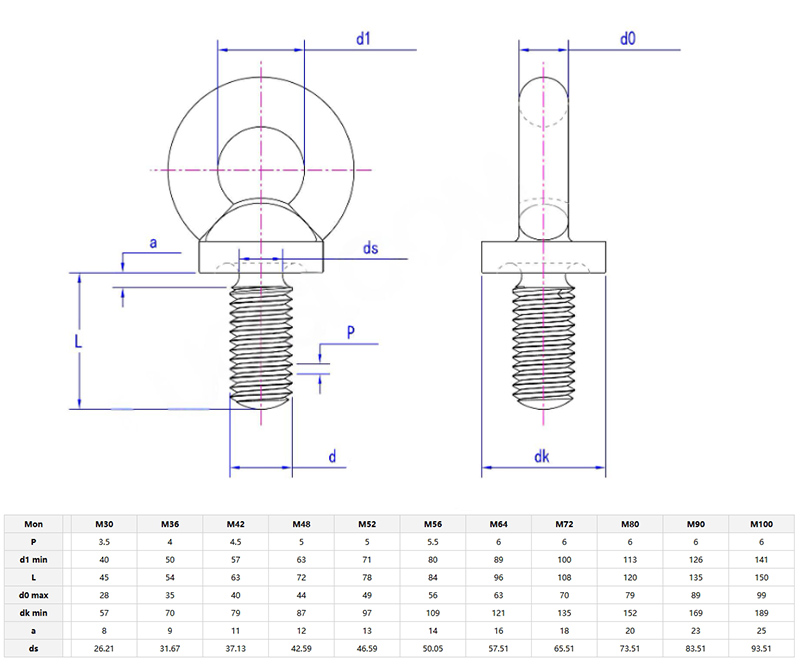

Product parameters

FAQ

Q: Can screw eye be used for angled lifts, or are they only for vertical loading?

A: Standard screw eye are meant for straight-up vertical lifting. If you use them at an angle, it puts sideways stress on them, which can cut their weight capacity by as much as 75% and make them more likely to fail. For angled jobs, you should use shoulder eye bolts that have a 90-degree shoulder—these help spread out the sideways force safely. Always check the weight charts to see how much you need to reduce the load when using them at an angle.

Using regular eye bolts (not the shouldered kind) for angled lifting can void the warranty and isn’t safe. If you need to lift loads in multiple directions, just let us know—we can provide specialized lifting gear for those situations.