Robustly Constructed Compression Spring

Send Inquiry

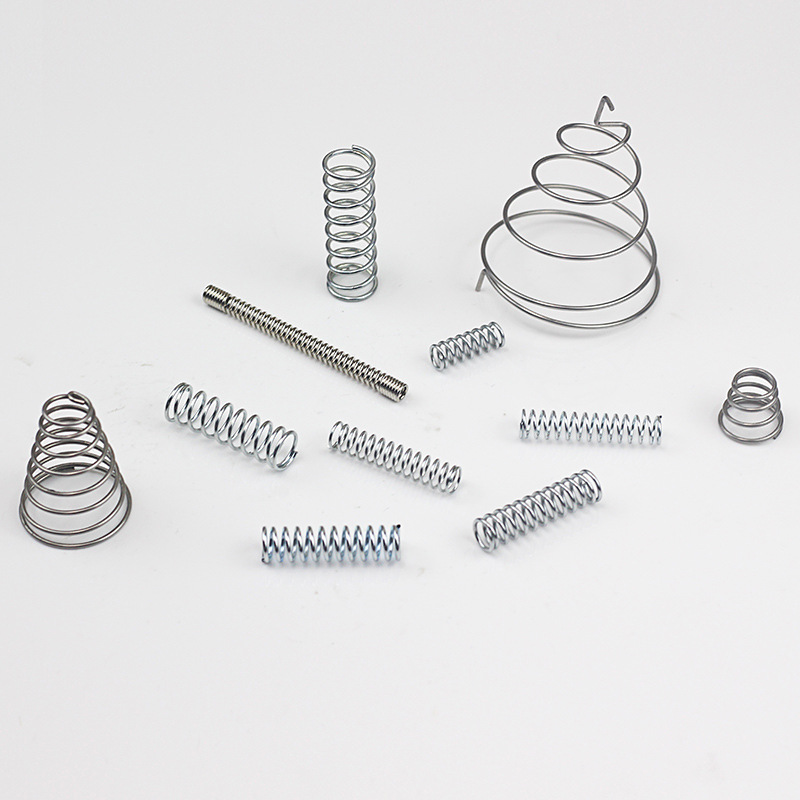

Robustly Constructed Compression Springs are commonly used in packaging machinery - they help with sealing and cutting parts, and require the generation of stable and continuous force.

These springs usually have closed ends, which makes them more stable. We rely on the industry's most advanced production technology, optimize production processes, strictly control cost losses, and successfully give it excellent cost-effectiveness while ensuring high product quality - allowing you to obtain a product experience that far exceeds your expectations with a more reasonable investment. As long as your order quantity exceeds 4,500 units, we will sincerely provide discounts to help you control procurement costs.

We have a variety of colors, like the zinc-chrome yellow, which is inherently rust-resistant and extremely durable. We source from reliable manufacturers, so we deliver quickly. If you order more, the price is negotiable!.

Featuring sturdy, waterproof packaging for guaranteed safe delivery. Each compression spring is tested to determine its load-bearing capacity and service life. We carry out all these operations in accordance with the ISO 9001 certification protocol.

Product Details

In the maritime field, compression springs have a wide range of applications, typical examples of which include cabin door devices and navigation systems. It needs to have excellent resistance to salt water corrosion to effectively block the occurrence of rust reactions.

These springs are made of marine-grade materials and have a specific coating. We sell directly to other countries (direct export), which makes our prices competitive. If you order more than 5500 units, you can enjoy a discount.

The standard color is navy blue - it goes very well with the components on the ship. We ship quickly by sea or air, and bulk orders are cost-effective.

The springs are packed in waterproof sealed bags, which are then placed in sturdy boxes. Before the product is shipped, we will initiate a special quality inspection process to not only verify its waterproofness and sealing, but also test its load-bearing, drop resistance and other strength indicators to ensure that it meets the requirements of use. All of this is in accordance with the DNV-GL standard.

Product Benefits

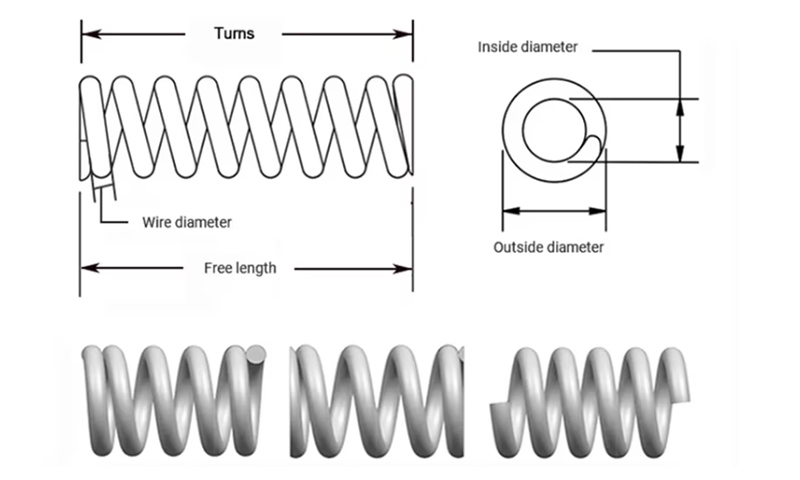

The spring rate (k) is the load per unit deflection (e.g., N/mm). It defines the Robustly Constructed Compression Spring's stiffness. The stiffness of a compression spring with a solid structure is its "hardness against compression": the force required to shorten it by 1 unit length is the stiffness. The force generated by a spring during compression is the key to a product's feel. To ensure optimal functionality and excellent feel, we perform precise calculations at the very beginning of the design process.