Pin Without Head

Send Inquiry

A pin without head is just a basic, flat fastener. It’s used when you don’t want anything sticking out but still need something to keep parts secure. Unlike regular pins that have a bulky head, this one doesn’t,so it stays low and saves space. Even though it’s slim, it’s strong enough for heavy jobs. The smooth, round shape helps spread weight evenly, which is why you’ll see it in stuff like car parts, small electronics, or machines where precision matters. Since there’s no head, it fits neatly into tight spots or places where you need things to sit flat, like hidden joints. Most are made from stuff like stainless steel or strong alloys, so they hold up under stress and don’t rust easily. Engineers like using these in tight spaces because they’re simple, reliable, and don’t get in the way.

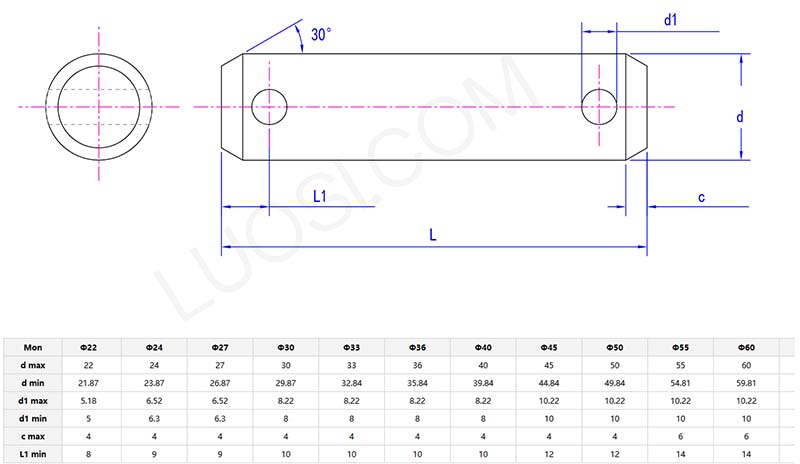

Size

Pin without head come in standard sizes: diameters from 1mm to 50mm and lengths from 3mm to 300mm. There are metric versions (following ISO 8734) and imperial ones (following ANSI B18.8.2) to fit global manufacturing needs. Tolerance levels from h6 to h9 mean they can press-fit tightly into holes in housings.

For custom needs, some have spiral grooves to hold adhesive, and others have textured edges for use in plastic composite parts. High-precision options have polished surfaces with extremely tight roundness (cylindricity under 0.005mm), ideal for bearings. In heavy industries, bigger pins up to 100mm in diameter have slightly tapered ends (a 1:50 taper) to make installing them easier.

All sizes meet RoHS and REACH regulations, so they can be used worldwide without issues.

Materials and standards

Q: What materials are typically used in manufacturing pin without head, and do they meet international standards like ASTM or DIN?

A: This pin is usually made from carbon steel, stainless steel, or alloy steel, depending on what the application needs. Materials such as ASTM A576 carbon steel or DIN 1445 stainless steel provide strong tensile strength and help resist corrosion. These pins go through strict quality tests to meet standards like ISO, ASTM, or DIN, which ensures they hold up well in heavy-load situations. For specific needs, we can adjust the materials to meet certain industry certifications.