Parallel Pin

Send Inquiry

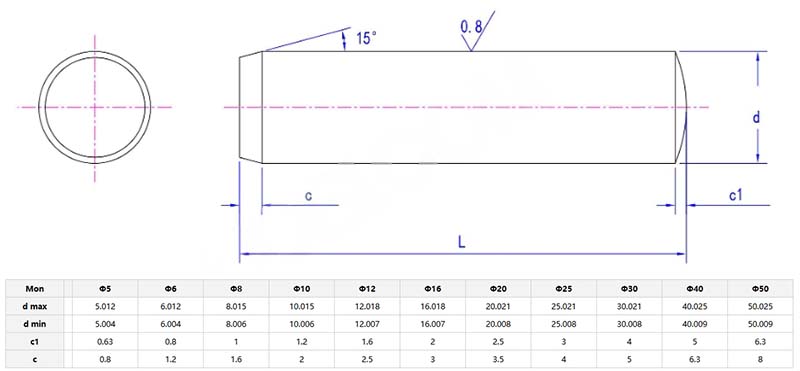

Parallel pins are a type of positioning pins, also called cylindrical pins. When used, they are inserted into the holes of the connecting objects to connect two parts. Xiaoguo Factory provides pins of various sizes. Contact us for more sizes. This type of positioning pin has low cost, simple structure, convenient use, high positioning accuracy, and strong load-bearing capacity. However, interference fit will make it difficult to disassemble and parts will be easily damaged. Do not disassemble too many times, otherwise the interference will be reduced and the positioning will be inaccurate.

Materials

The performance of parallel pin depends on the material they’re made from. For basic uses, they often use AISI 1045 carbon steel. In marine settings, where there’s a lot of moisture, AISI 316L stainless steel is the go-to choice. High-speed steel (HSS) pins are tough enough for rough, abrasive environments, while aluminum pins are picked when keeping weight low is important. Certifications like RoHS or REACH make sure they meet environmental rules. Testing the material,checking things like how strong it is (tensile strength) and how hard it is,helps ensure they work the same way every time, especially in applications where reliability matters a lot.

维护

如果你想让平行销耐用,就需要定期检查和维护它。主要检查它的磨损、生锈或弯曲情况。如果发现任何问题,你需要及时更换或维护。如果针子用于摩擦较大的地方,你需要使用与材料相匹配的润滑脂。对于不锈钢的,偶尔用温和的溶剂清洗,防止脏掉。存放在干燥且温度可控以避免生锈的地方。

定制版

问:平行销可以在尺寸和公差方面进行定制吗?

答:可以,这款销可以根据你需要的直径、长度和公差等级定制。对于公制引脚,有ISO 2338这样的标准。他们通过精密磨削确保公差非常严格,比如H8或M6,这样销钉才能很好地嵌入组件中。你也可以选择定制涂层或表面处理,比如锌镀层。只要提供详细的图纸或规格,让它们符合你的机械或工具需求。

产品用途

XIAO GUO在这里使用的紧固件用于对齐零件,并使不同机器上的部件保持固定。你会发现它被用于变速箱、电机,甚至家用电器中,这些设备需要精准定位——在运行过程中没有额外的松弛或换挡。机械师用它来修理,工厂装配线也依赖它来保持产量稳定。它能紧密插入预钻孔中,所以不需要复杂的工具来安装。我们是一家总部位于中国的工厂和供应商,提供批量、批发和定制尺寸的零件。你可以现货购买或索取报价,它符合基本工业标准,没有任何不必要的附加内容。

产品材料

该部件由常见的工业级钢、不锈钢或黄铜制成——这些材料是大多数买家根据自身需求要求的。钢制版本适用于成本优先的通用应用;不锈钢适用于潮湿或户外环境,需要防锈;黄铜适用于低摩擦作业或电气设备,这些设备对耐腐蚀性很重要。除非客户要求定制规格,否则我们不使用稀有或昂贵的合金。每批批次都会检查,确保材料在运输前符合厚度和硬度的要求。作为制造商和供应商,我们以低价提供这些材料,批量订购可打折,若想先测试质量,也可免费获得样品。