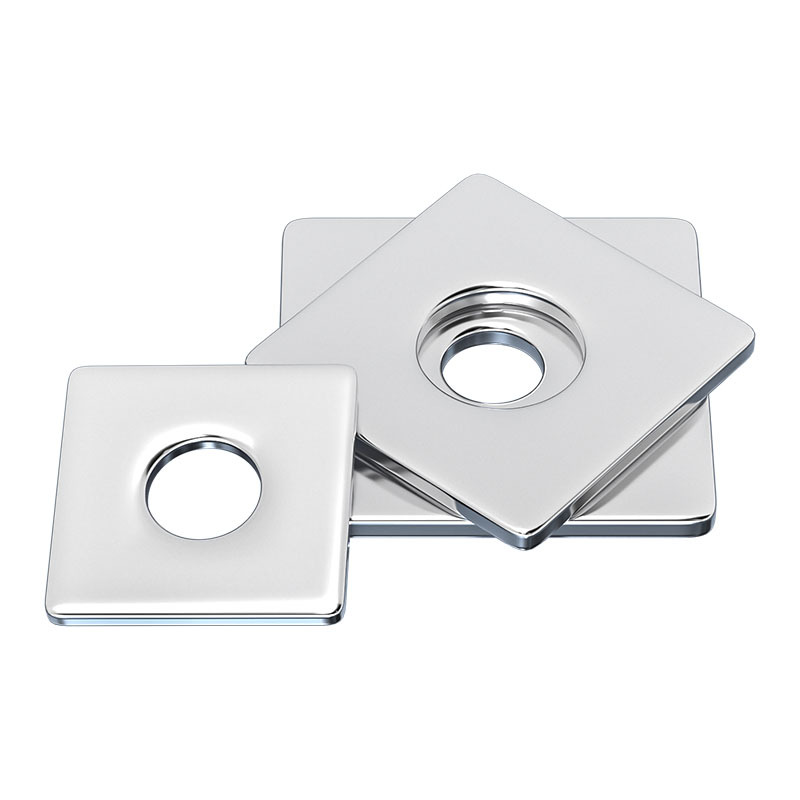

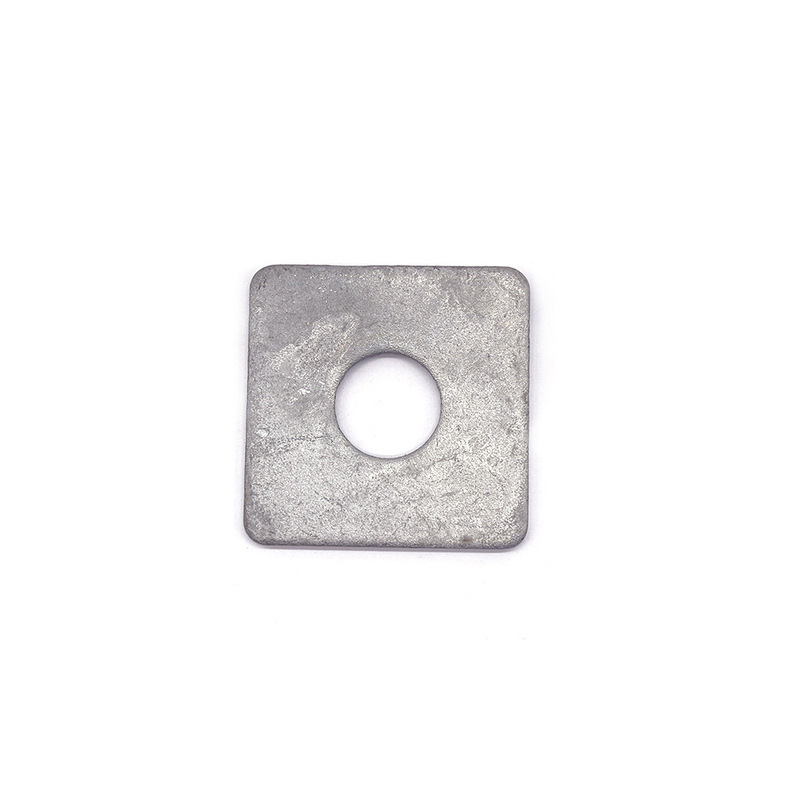

Non Marring Square Washer

Send Inquiry

In the electrical field, people use Non Marring Square Washers for grounding and bonding work.The washers' structural design allows them to fit tightly against the contact surface, ensuring stable current flow and reducing line resistance. The joints also have excellent anti-rust properties, effectively extending the service life of the components; and the washers are made of high-quality and highly conductive materials such as copper and brass, which can provide reliable protection for the safe and stable operation of electrical equipment.

Product Benefits

Non Marring Square Washers are pretty common in furniture making too—especially when putting together frames or attaching legs. They have a bigger surface that spreads out pressure well, so they don’t damage wood or composite materials. That’s useful for stuff people use a lot, like office chairs or tables. The square design gives the gasket excellent assembly positioning capabilities, effectively ensuring precise alignment during installation. This feature not only significantly improves production and assembly efficiency, making the manufacturing process smoother and more efficient, but also reduces component loss due to installation deviations, thereby helping to extend the overall life of the furniture.

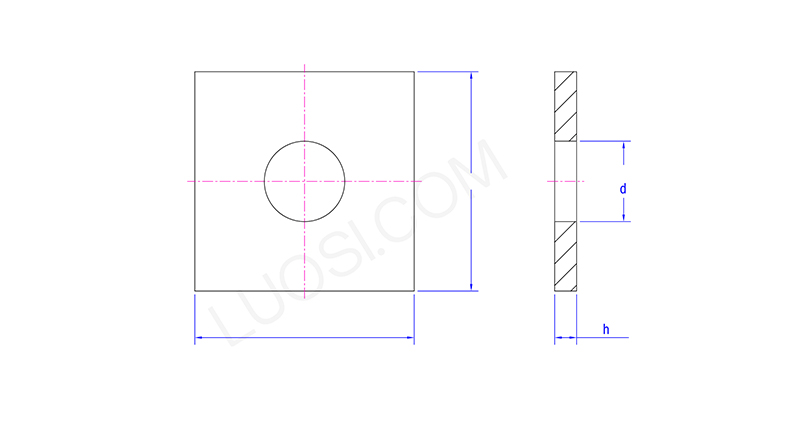

| Mon |

Φ6 |

Φ8 |

Φ10 |

Φ12 |

Φ14 |

Φ16 |

Φ20 |

Φ24 |

| d max | 6.4 | 8.5 | 10.5 | 12.5 | 14.5 | 16.5 | 21 | 25 |

| d min | 6.15 | 8.25 | 10.25 | 12.25 | 14.25 | 16.25 | 20.75 | 24.75 |

| s min | 16.4 | 19.4 | 22.4 | 29 | 32.1 | 35.8 | 42.3 | 55.3 |

| h | 1.8 | 1.8 | 1.8 | 2.9 | 2.9 | 2.9 | 3.9 | 3.9 |

FAQ

Q: Can you provide custom sizes for the Non Marring Square Washer outside of your standard catalog?

A:Absolutely. We specialize in custom fabrication. You can provide the specific outer dimension, inner hole diameter, and thickness requirements, and we can produce a non-standard Non-marring square washer to your exact specifications. Custom Non Marring Square Washer orders typically have a slightly higher unit cost and a longer lead time for tooling setup.