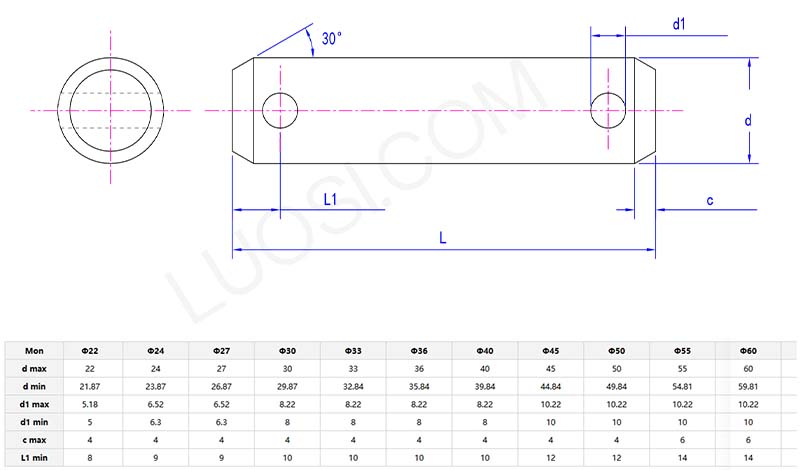

Non Headed Pin Shaft

Send Inquiry

The non headed pin shaft is really important in modern engineering. It’s used as pivot points in CNC machine tool chucks, as alignment guides in the trackers that move photovoltaic panels, and as parts that hold things in place in medical imaging devices. Because it can be mounted flush (so it doesn’t stick out), it works well for smooth aerodynamic surfaces on drones and for internal parts in luxury cars where any bumps or protrusions aren’t allowed.

In consumer electronics, it holds the hinges on foldable smartphones together and keeps micro-drive systems secure. Agricultural machinery uses these pins in seed meter assemblies because their shape helps shed debris (like dirt or small particles) that might get stuck.

Recently, there are new versions treated with cryogenic processes for use in superconducting equipment and MRI machines. This shows how adaptable the headless pin is across different cutting-edge technologies.

About us

Xiaoguo® factory make custom non headed pin shaft for different needs. For example, we use magnetic 430F stainless steel when integrating sensors, and non-magnetic beryllium copper in places where explosions are a risk. Aerospace applications use hollow-core designs to cut weight but still keep the pin rigid when twisted. Some pins have RFID chips inside, which lets factories track assets using IoT in assembly lines.

In really high temperatures, nickel-based superalloys like Inconel 718 work fine up to 700°C. For medical use, there are grades made from Ti-6Al-4V ELI alloy with electropolished surfaces that meet ASTM F136 standards. Clients can ask for special coatings too—like molybdenum disulfide for vacuum setups or chromate conversion to help paint stick better. These custom changes mean the headless pin can handle specific engineering problems.

Surface treatment

Q: Are surface treatments like zinc plating or passivation available for non headed pin shaft to prevent corrosion?

A: Headless shaft pin can get coatings like zinc plating, hot-dip galvanizing, or passivation to fight rust and protect against chemicals. Zinc coatings add a 5-15µm protective layer, which works well for outdoor or marine use. If you need them for food equipment or medical devices, go for electropolished stainless steel versions,they help avoid contamination. Just tell the manufacturer about the environment they’ll be in (humidity, temperature, chemicals around) to pick the best coating. This way, the pins stay reliable long-term without losing their mechanical strength.