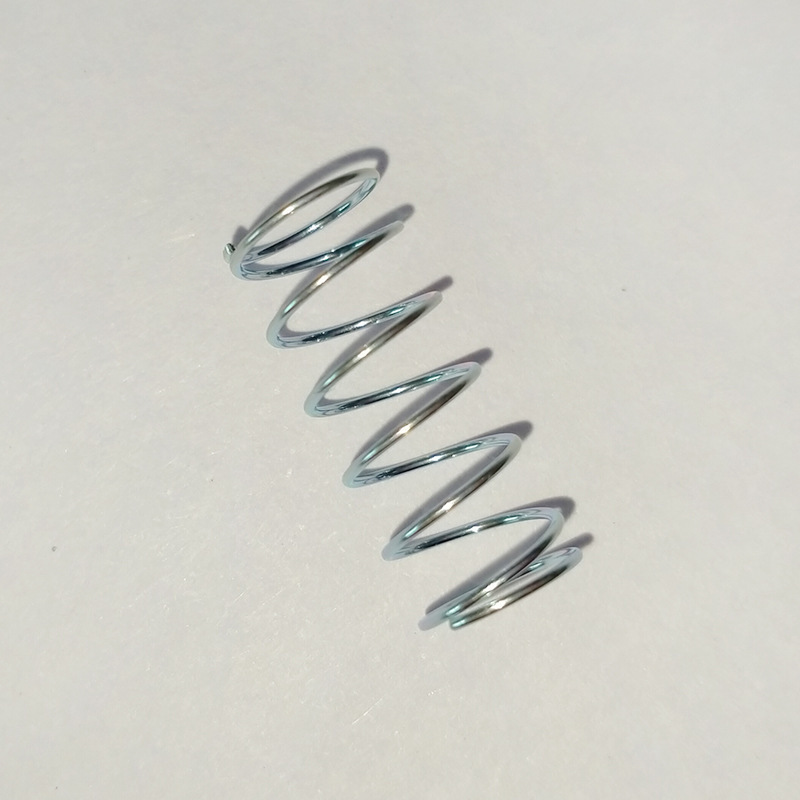

Industry Proven Spiral Spring

Send Inquiry

Industry Proven Spiral Springs are applied in various medical devices, such as surgical staplers, drug delivery pumps, and retracting components in minimally invasive surgical tools. In these devices, Industry-Proven Spiral springs can provide controllable and reliable rotational energy, and they are of small size.

They have biocompatible coatings and can exert force in a predictable manner. These two features are crucial for ensuring the normal operation of the equipment during important medical procedures - because if there is a malfunction, it would not be acceptable.

Product Details

In aerospace systems, helical springs are used in components that need to store and release energy in confined spaces. For instance, they are found in some actuator devices used to deploy antennas or solar panels.

The helical springs here are made of high-performance alloys. This enables them to remain stable in extreme environments and generate specific and reliable torque. Its performance is the key to mission success, so it must pass rigorous testing and obtain compliance certification to meet the special requirements of the aerospace field.

FAQ

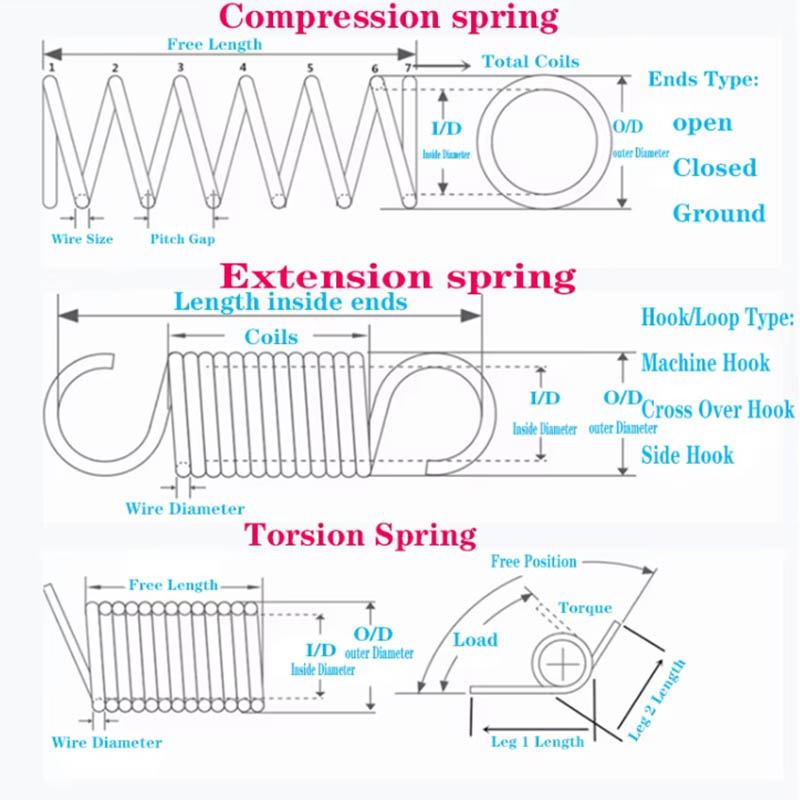

Q:What materials do you typically use for manufacturing high-performance spiral springs?

A: For standard industry-proven coil springs, we prefer high-carbon spring steels such as 1095 steel. This is primarily due to their excellent yield strength and fatigue life, meeting performance requirements. For highly corrosive environments or applications with special non-magnetic requirements, we offer stainless steel (model 302/316) and beryllium copper to meet stringent usage requirements. The material choice is critical for the longevity and reliability of your Industry Proven Spiral Spring, especially in dynamic applications with thousands of extension-retraction cycles.