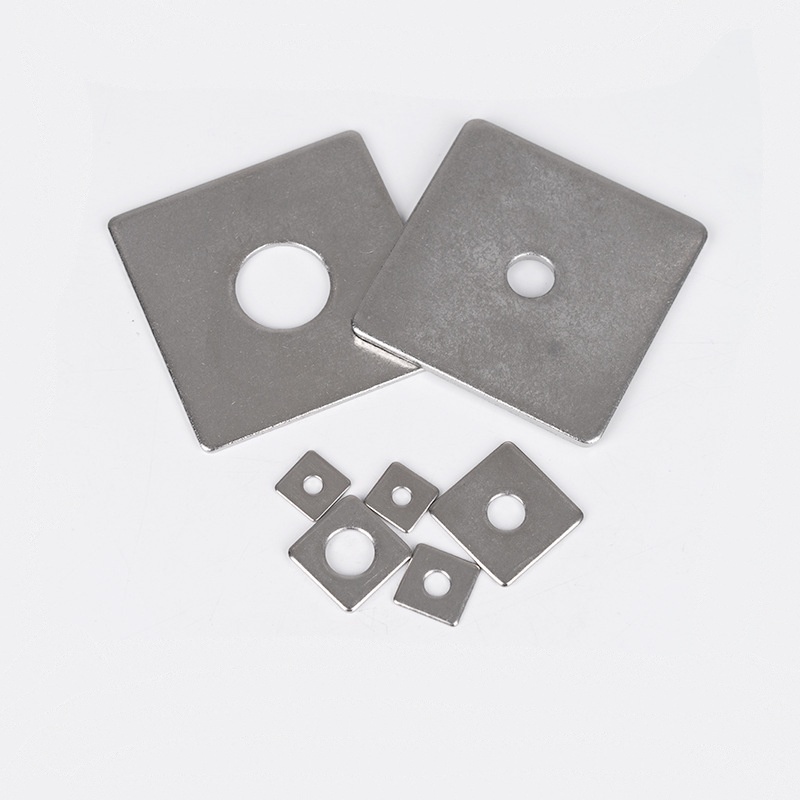

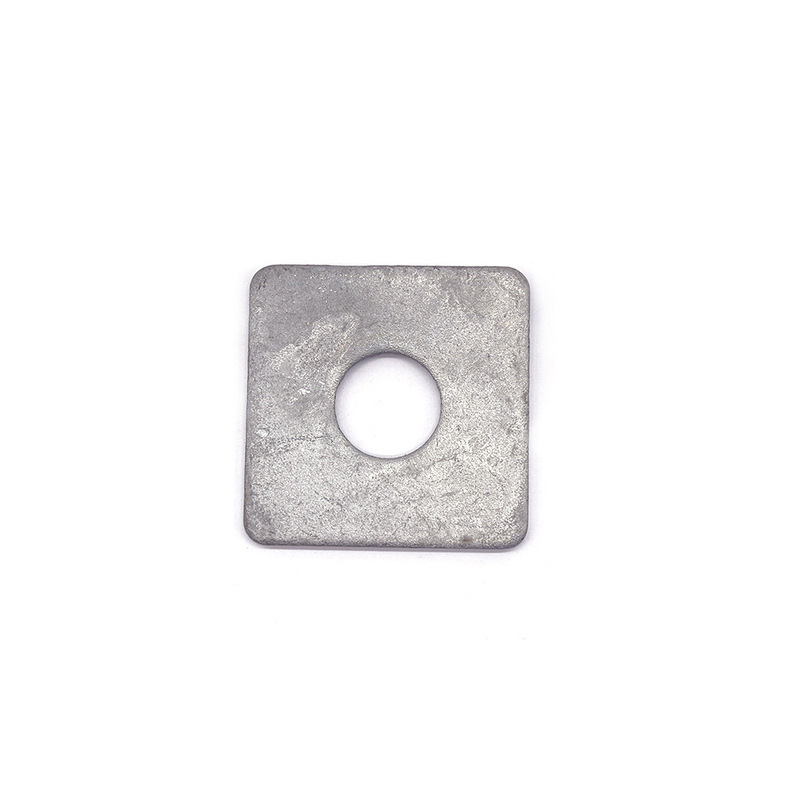

Industrial Grade Square Washer

Send Inquiry

Quality control for industrial grade square washers starts with picking the right materials. They test the hardness of the raw materials, check how much tension they can withstand, and check whether the materials are rust-resistant. In addition, they closely monitor each step of the production process to ensure that the washers meet the required dimensions - during this process, they use calipers and micrometers to measure samples.Doing all these checks means every washer meets the required size limits and works like it should for whatever it’s used for.

Quality Assurance

Every batch of industrial grade square washers gets checked before they’re shipped out. Quality inspectors make sure the size is right, the surface looks good, and the coating’s thick enough. They also do tests to see if they work—like checking if they fit with regular bolts and nuts. This step finds any parts that don’t match the design specs, so they can fix things before sending the washers out. If customers want, they can ask for inspection reports to feel more sure about the order.

FAQ

Q:What surface treatment options are available for your industrial grade square washers?

A:We offer various surface treatments for our square washer products to enhance performance and durability. Common options include zinc plating (blue/clear or yellow chromate) for good corrosion resistance, hot-dip galvanizing for harsh environments, black oxide for a mild protective layer, and plain oiled finish for temporary rust prevention.

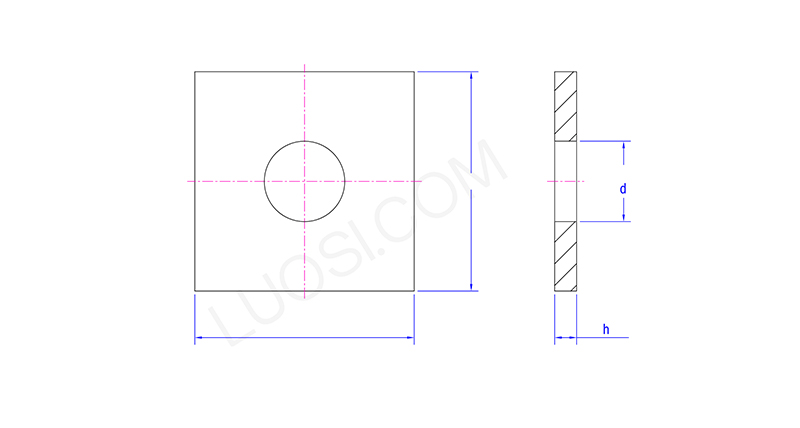

| Mon |

Φ6 |

Φ8 |

Φ10 |

Φ12 |

Φ14 |

Φ16 |

Φ20 |

Φ24 |

| d max | 6.4 | 8.5 | 10.5 | 12.5 | 14.5 | 16.5 | 21 | 25 |

| d min | 6.15 | 8.25 | 10.25 | 12.25 | 14.25 | 16.25 | 20.75 | 24.75 |

| s min | 16.4 | 19.4 | 22.4 | 29 | 32.1 | 35.8 | 42.3 | 55.2 |

| h | 1.8 | 1.8 | 1.8 | 2.9 | 2.9 | 2.9 | 3.9 | 3.9 |