High Precision Metric Square Head Bolts

Send Inquiry

It’s important to check High Precision Metric Square Head Bolts regularly if you want them to hold up long-term—especially in important spots or places where they’re out in the open. Look for rust, damaged threads, stretching, or if the head is bent.

Putting some lube on them when you put them in helps get the tightness right and can keep them from rusting later. For carbon steel bolts: When damage is found on the surface coating, repair measures should be taken as a priority to restore the integrity of the coating as much as possible and avoid exposure of the base material and rust. If a bolt is really rusted, damaged, or stretched too much, replace it right away.

For those places that are prone to rust, if you use stainless steel, a material that is not easy to rust, you don’t have to go through the trouble of maintenance.

Product Benefits

High Precision Metric Square Head Bolts are useful in spots where their specific traits matter: wrenches grip them better, they sit lower, they match old designs, or they work in tight spaces. Hex bolts are more common in modern setups, though. But metric square head bolts still matter because they hold up well when you need to tighten them a lot, they work with older designs, and they’re good for wood construction. They’re still an important, specialized option among metric fasteners—reliable in the situations where their shape works best.

FAQ

Q: Can you provide material certification (e.g., Mill Test Certificate) for High Precision Metric Square Head Bolts, especially for grades 8.8 and higher?

A: Sure. We provide full material docs for High Precision Metric Square Head Bolts—like Mill Test Certificates (MTCs) or Certificates of Conformance (CoC). This is especially true for higher grades, such as 8.8, 10.9, and stainless steel ones. These traceable papers show the chemical makeup and mechanical properties of the metric square head bolts we supply.

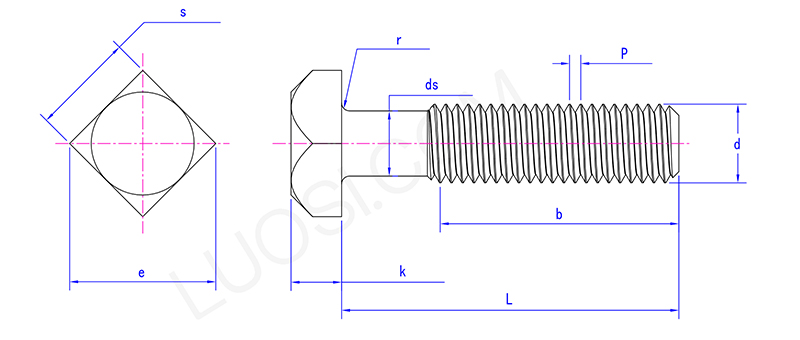

Product Parameters

| Mon | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M36 | M42 | M48 |

| P | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 4 | 4.5 | 5 |

| ds min | 12.70 | 14.70 | 16.38 | 18.38 | 20.38 | 22.05 | 25.05 | 27.73 | 33.40 | 39.08 | 44.75 |

| ds max | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 36 | 42 | 48 |

| e min | 26.21 | 30.11 | 34.01 | 37.91 | 42.9 | 45.5 | 52 | 58.5 | 69.94 | 82.03 | 95.03 |

| k min | 8.55 | 9.25 | 11.1 | 12.1 | 13.1 | 14.1 | 16.1 | 17.95 | 21.95 | 24.95 | 28.95 |

| k max | 9.45 | 10.75 | 12.9 | 13.9 | 14.9 | 15.9 | 17.9 | 20.05 | 24.05 | 27.05 | 31.05 |

| r min | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1.2 | 1.6 |

| s max | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 55 | 65 | 75 |

| s min | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 53.8 | 63.1 | 73.1 |