High Load Disc Shaped Spring

Send Inquiry

In substations and switch cabinets, High Load Disc Shaped Spring washers are used to maintain a stable contact pressure at bolted electrical connections. This is crucial for safety and the performance of the equipment. The design prevents loosening during thermal expansion or vibration.

We offer very competitive prices for the electrical industry. If the order quantity reaches the tray specification, a discount can be enjoyed. They usually come with a non-conductive coating. It eliminates redundant packaging and maintains a simple style while maintaining excellent sturdiness to protect items from damage.

It eliminates redundant packaging and maintains a simple style while maintaining excellent sturdiness to protect items from damage. Before shipment, each spring will be checked for its size and whether the coating is intact.

Product Details

High Load Disc Shaped Spring are commonly used in agricultural machinery, such as plows and harvesters - mainly for rotating points and tensioning devices. These springs are designed to function properly in environments with high wear and corrosion.

Our prices are suitable for agricultural equipment manufacturers, and we also conduct seasonal promotional activities. The common surface treatment is a thick epoxy coating, usually green or red. We effectively optimize and reduce transportation costs by adopting reliable ground transportation solutions.

This packaging is not only strong enough to withstand collisions and squeezing during transportation, but also wind and rain. It can protect the contents intact even in extreme weather, making it extremely practical. We inspect the quality by testing the load and deformation of the batches to ensure they can meet the needs of agricultural use.

|

Disc-shaped spring standard version |

|||||||||

|

|

Geometric parameters |

Mechanical properties |

Weight |

||||||

|

f=0.50h f=0.75h |

|||||||||

|

|

D |

d |

t |

h/t |

F |

P |

F |

P |

kg/100 |

|

C |

8.0 |

4.2 |

0.20 |

0.45 |

0.125 |

33 |

0.188 |

39 |

0.06 |

|

B |

8.0 |

4.2 |

0.30 |

0.55 |

0.125 |

89 |

0.188 |

118 |

0.09 |

|

A |

8.0 |

4.2 |

0.40 |

0.65 |

0.100 |

147 |

0.150 |

210 |

0.11 |

|

C |

10.0 |

5.2 |

0.25 |

0.55 |

0.150 |

48 |

0.225 |

58 |

0.11 |

|

B |

10.0 |

5.2 |

0.40 |

0.70 |

0.150 |

155 |

0.225 |

209 |

0.18 |

|

A |

10.0 |

5.2 |

0.50 |

0.75 |

0.125 |

228 |

0.188 |

325 |

0.22 |

|

D |

12.0 |

6.2 |

0.60 |

0.95 |

0.175 |

394 |

0.262 |

552 |

0.39 |

|

C |

12.5 |

6.2 |

0.35 |

0.80 |

0.225 |

130 |

0.338 |

151 |

0.25 |

|

B |

12.5 |

6.2 |

0.50 |

0.85 |

0.175 |

215 |

0.262 |

293 |

0.36 |

|

A |

12.5 |

6.2 |

0.70 |

1.00 |

0.150 |

457 |

0.225 |

660 |

0.51 |

|

C |

14.0 |

7.2 |

0.35 |

0.80 |

0.225 |

106 |

0.338 |

123 |

0.31 |

|

B |

14.0 |

7.2 |

0.50 |

0.90 |

0.200 |

210 |

0.300 |

279 |

0.44 |

|

A |

14.0 |

7.2 |

0.80 |

1.10 |

0.150 |

547 |

0.225 |

797 |

0.71 |

|

C |

16.0 |

8.2 |

0.40 |

0.90 |

0.250 |

131 |

0.375 |

154 |

0.47 |

|

B |

16.0 |

8.2 |

0.60 |

1.05 |

0.225 |

304 |

0.388 |

410 |

0.70 |

|

A |

16.0 |

8.2 |

0.90 |

1.25 |

0.175 |

697 |

0.262 |

1013 |

1.05 |

|

C |

18.0 |

9.2 |

0.45 |

1.05 |

0.300 |

185 |

0.450 |

214 |

0.68 |

|

B |

18.0 |

9.2 |

0.70 |

1.20 |

0.250 |

417 |

0.375 |

566 |

1.03 |

|

A |

18.0 |

9.2 |

1.00 |

1.40 |

0.200 |

865 |

0.300 |

1254 |

1.48 |

If you need any other data, pleasecontact us. We will provide you with moredetailed parameters.

FAQ

Q:Are there specific installation guidelines for a spring?

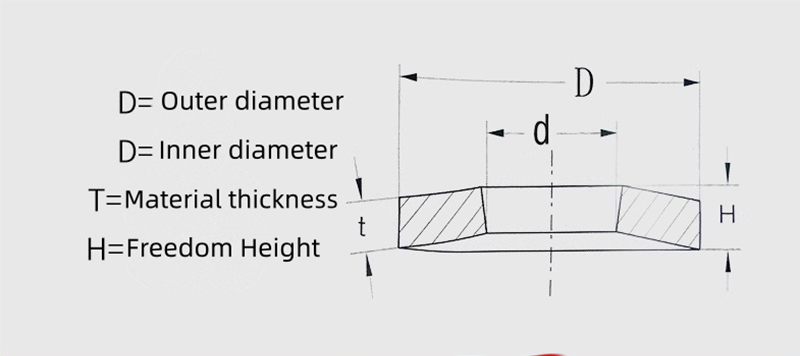

A: Yes, correct installation is crucial. The High Load Disc Shaped Spring must be seated squarely on flat, parallel surfaces. We provide detailed technical data sheets with each order, guiding the proper installation and handling of the spring to ensure optimal performance and safety.