Flexible T Slot Nut

Send Inquiry

Before any Flexible T Slot Nut gets sent out of the factory, it goes through a final quality check right before shipping. They will randomly select samples from each batch of finished products and check one by one to see if there are any quality problems. Problems such as messy thread ends, dimensional deviation, and too thin electroplating layer are all within the scope of investigation.

The primary purpose of this inspection is to verify that the order matches the customer's order and to ensure that quality requirements are met. Why is this final step so critical? Because it acts as a "last checkpoint," preventing defective T-slot nuts from being shipped.That way, customers only get parts that are sure to work right.

Basically, nothing leaves the factory without one last look. They grab a few nuts at random, make sure they’re not faulty, and only then send them out—so you don’t get stuck with a nut that doesn’t work.

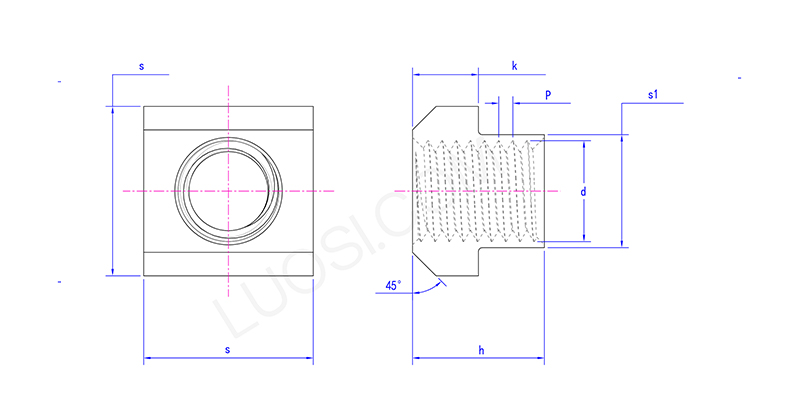

| Mon | M6 | M8 | M10 | M12 | M16 | M20 | M24 | M30 | M36 | M42 | M48 |

| P | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 |

| s1 max | 7.7 | 9.7 | 11.7 | 13.7 | 17.7 | 21.7 | 27.7 | 35.6 | 41.6 | 47.6 | 53.6 |

| s1 min | 7.5 | 9.5 | 11.4 | 13.4 | 17.4 | 21.4 | 27.4 | 35.3 | 41.3 | 47.3 | 53.3 |

| s max | 13 | 15 | 18 | 22 | 28 | 35 | 44 | 54 | 65 | 75 | 85 |

| s min | 12.5 | 14.5 | 17.5 | 21.5 | 27.5 | 34.5 | 43 | 53 | 64 | 74 | 84 |

| h | 10 | 12 | 14 | 16 | 20 | 28 | 36 | 44 | 52 | 60 | 70 |

| k max | 6 | 6 | 7 | 8 | 10 | 14 | 18 | 22 | 26 | 30 | 34 |

| k min | 5.5 | 5.5 | 6.5 | 7.5 | 9.5 | 13.5 | 17 | 21 | 25 | 29 | 33 |

Possess international quality certification

Good manufacturers generally have international quality certifications such as ISO 9001. This certification is equivalent to a clear set of "quality rules" - whether designing Flexible T Slot Nuts, producing them, or even shipping them to customers, they can follow these rules to ensure the same high quality of nuts every time. Having this means they’re serious about making good nuts.

Additionally, the materials and finishes used may comply with other relevant standards (such as the RoHS standard for the restriction of hazardous substances). It should be noted that you will not automatically receive a physical inspection certificate for each T-slot nut, but if required, you can request it from the other party, and they can usually provide the corresponding Certificate of Conformity (CoC). That document tells you exactly how the product meets the required standards.

Basically, these certifications show the manufacturer knows how to keep quality steady. And if you need proof the nuts meet specific rules, just ask for that CoC—they’ll hook you up.

Q: What is your MOQ and lead time for custom Flexible T Slot Nut orders?

A:Our standard Minimum Order Quantity (MOQ) is negotiable. Lead times for custom Flexible T-slot nut orders, such as special sizes or materials, typically range from 20-30 days after confirmation. We offer flexible support for both small and large projects.