Fatigue Resistant Stretching Spring

Send Inquiry

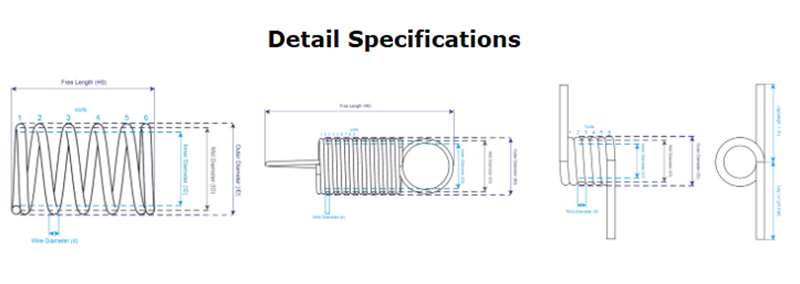

Fatigue Resistant Stretching Spring are widely used in the automotive industry - for instance, in the return mechanism of the throttle and the brake pedal. They can maintain a stable tension and operate reliably.

These springs usually have different types of end rings, such as full rings or hook-shaped rings, which makes them easy to install. We adopt automated large-scale production, so our prices are quite competitive. If you order more than 1,000 units, you can enjoy a 5% discount.

You can choose the standard surface treatment method: either galvanized or black oxide. We deliver the springs quickly through courier companies, so they can be delivered to you promptly.

We use a dual packaging solution of individual plastic bags and sturdy cartons. This solution effectively prevents spring entanglement during transportation and prevents damage from external forces, ultimately ensuring that the product arrives in perfect condition.

Product Benefits

In the field of consumer electronics, Fatigue Resistant Stretching Spring are crucial for products such as retractable cables, selfie sticks, and laptop pop-up devices. These devices require precise stretching control - thus the springs play a key role.

These springs are usually of small diameter, with tightly wound coils and the ends precisely polished. We produce them at an economical price, so the price of each product is very low. If you order more than 5,000 pieces, free shipping will be provided.

They usually have a layer of passivation treatment to prevent rusting. For international orders, we use fast air freight - so they can be delivered quickly without any delay.

The packaging design is to absorb vibrations and prevent water ingress. This way, the springs will not be damaged by environmental factors or rough handling.

Commonly used materials

We commonly use high-carbon steel for general-purpose Fatigue Resistant Stretching Springs and stainless steel (302 or 316) for superior corrosion resistance. If your application involves outdoor exposure or marine operations, you must choose 316 stainless steel springs. They directly address the rust and short lifespan issues of standard springs in humid, high-salt environments, and are proven to be the optimal choice through field testing. This material ensures your stretching spring withstands harsh conditions without rusting, providing a long service life and consistent tensile force.