Dynamically Engineered Torsion Spring

Send Inquiry

In industrial equipment, Dynamically Engineered Torsion Springs are of vital importance - they are used in the balancing systems of doors and covers, and also in complex assembly line components that require precise rotational force.

As a high-strength dynamically designed torsion spring, its core advantage lies in its ability to withstand wear and tear from repeated use. Even under high pressure, it can always maintain stable spring force, providing reliable force output guarantee for the equipment. If they are damaged, the equipment may need to stop operating, and there will be potential safety hazards.

This is why the lifespan and reliability of these springs are so crucial - this ensures that manufacturing and processing factories operate efficiently and avoids unexpected downtime.

Product Details

In the aerospace and defense fields, they use highly specialized Dynamically Engineered Torsion Springs - such as those used for control surface devices, landing gear systems, and various instrument panels.

These springs are made of high-quality alloys. The reason is that they need to meet demanding requirements: they must have good strength relative to their own weight, have a long fatigue life, and be able to withstand damage caused by harsh environments, etc.

In this case, the working condition of even one spring plays a decisive role in the success of the mission. Therefore, they need to meet three key requirements: pass rigorous design inspections, have full tracking of each stage of production, and adhere to the strictest quality standards.

FAQ

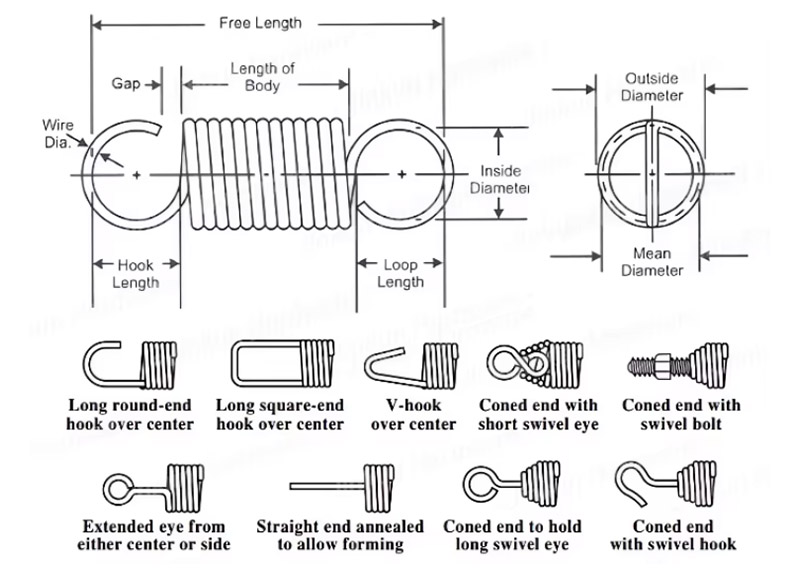

Q:How do you determine the maximum deflection or rotation angle a spring can handle before failing?

A:The maximum rotation angle for a Dynamically Engineered Torsion Spring is determined by its design, material, and wire diameter. We calculate the stress levels at different deflections using specialized software. Exceeding the recommended angle induces high stress, leading to permanent set or breakage. Our technical specs always provide a safe maximum working angle for the spring to ensure longevity and prevent premature failure in your product's mechanism.